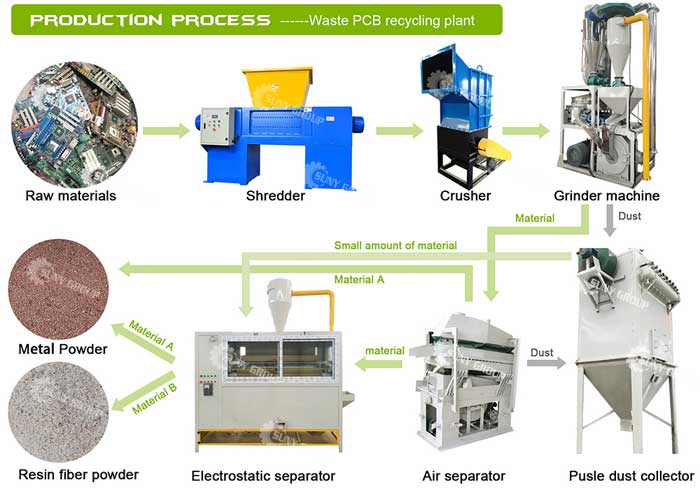

Process flow of circuit board recycling equipment

The circuit board recycling equipment can environmentally recycle the electronic components, copper, and non-metals (mainly glass fiber and resin) in the printed circuit board (PCB) for separation. The PCB light board is manually placed on the belt conveyor and sent to the two-stage crusher for crushing into granules, and then passes through the three-stage grinding, wind classification, gravity classification, screening classification, and high-voltage electrostatic sorting machine. , Separate and recycle copper and non-metal in PCB. The dual separation of air specific gravity separation and high-voltage electrostatic separation has high purity.

1.The circuit board is sent to the shredding and crushing machine by the conveyor.

2. Shred the circuit board to 3-5 cm, and then drop it directly into the crusher.

3. The crushed particles reach 1-2 cm, and then are sent to the three-stage mill by the feeding screw for grinding.

4. The pulverizer is an integrated water-cooled pulverizer, and it is pulverized under the condition of ensuring the normal temperature of the machine, and the mesh number reaches 50-80.

5. The pulverizer is equipped with a grading and screening machine, and the circuit board powder that reaches the required mesh during the grinding process enters the next step, and cannot meet the required recirculation.

The 6.50-80 mesh circuit board powder enters the next link of the wind specific gravity separator, and the primary separation is carried out according to the specific gravity of the copper powder and the resin fiber powder, and about 70% of the metal powder can be separated.

7. The powder separated by the specific gravity separator and the powder drawn by the upper suction enter the pulse dust collector. The powder discharged by the pulse dust collector contains a small amount of copper powder, and then it is sent to the high-voltage electrostatic separation equipment by the wind feeder. One step separation.

Precautions

Equipment prone to dust and odor (such as crushers, classifiers, screw conveyors, hoists, screening machines, electrostatic sorters, etc.) should be well sealed, continuous welds should be used for welding, and inspection doors, observation windows, etc. cannot be welded or The parts that need to be moved should be sealed with sealing strips.

The surface of the roller of the electrostatic separator is made of stainless steel, the length of the stainless steel surface of the roller is not less than 1.2m, the thickness of the roller is not less than 10mm, and the thickness of the outer stainless steel is not less than 1.5mm. The high-voltage generator of the electrostatic sorting machine is safe and reliable, and avoids easy contact with the human body.

Leave a Comment