Fully automatic e-waste recycling program for circuit board recycling

Scrap printed circuit boards are a mixture of glass fiber reinforced grease and a variety of metals, which is a typical electronic waste. The metal grade in the circuit board is equivalent to tens to hundreds of the metal grade in ordinary minerals, and the metal content is high. To reach 40%, most of them are copper, in addition to gold, aluminum, nickel, lead, silicon, etc., among which there are many rare metals; and the content of rich ore metals in nature is only 3%-5%. If it is not properly handled and disposed of, it will not only cause a large loss of useful resources, but also contain a large number of teratogenic, mutagenic, and carcinogenic substances such as cadmium brominated flame retardants, which will cause serious environmental and human health.

New type of waste circuit board recycling process and equipment. The production line is a fully automatic production line, using advanced physical recycling technology. It can effectively carry out mechanical crushing and recycling of all kinds of waste printed circuit boards, processing waste, waste electrical appliances, etc. The metal recovery rate is high, and the purity of the recycled metal is as high as 98%

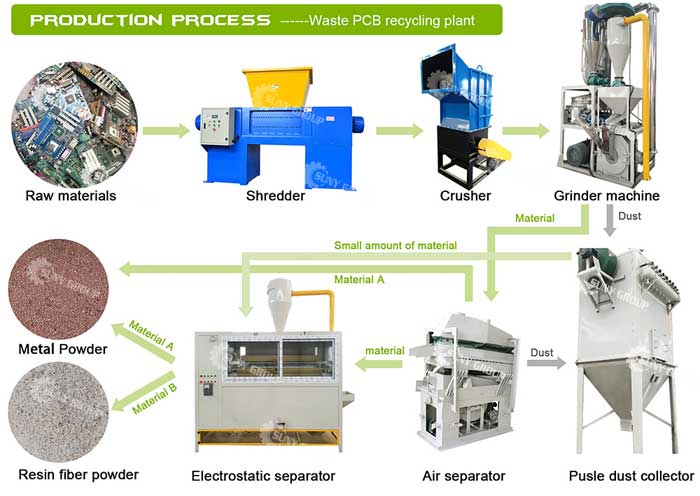

Whole line composition and process flow

The circuit board recycling and processing production line is mainly composed of conveyors, primary crushers, secondary crushers, magnetic separators, crushers, sorting machines and other auxiliary equipment. Its technological process is shown as in Fig. 1. After the discarded circuit boards are manually dismantled, the harmful electrical components such as batteries, transformers, etc. and reusable parts are removed, and the remaining parts are sent to the primary crusher via a scraper conveyor to crush the materials to less than 20mm , And then sent to the secondary crusher to crush the material to less than 5mm, the iron-containing material is separated by the magnetic separator, and the remaining material is crushed to the powder of about 2mm by the crusher, so that the copper in the multilayer machine board can be separated , The light dust is separated first by winnowing, and the materials with larger specific gravity are sent to the electrostatic separator to separate and recover about 20% of the non-ferrous metals (copper, etc.).

circuit board recycling and processing production line

Key process

The circuit board has high hardness and good toughness: it has good bending resistance; it is mostly flat, and it is difficult to separate metal and non-metal through one-time crushing; it contains many kinds of substances, and the metal is entangled after dissociation, etc. . The first-stage crusher uses a double-roller shearing method to cut large pieces of discarded circuit boards. It is mainly composed of driving body, spline shaft (knife shaft), blade, sparse plate, frame and other components. Among them, the spline shaft (knife shaft) and the blade are the key components to ensure the coarse crushing process. After the PCB is crushed to 20 mm, it is sent to the secondary crushing. The spline shaft (knife shaft) can optimize the power transmission of the blade. Through special heat treatment and ultrasonic testing, the blade and the distance ring can be easily removed for easy replacement of the blade. The blade is made of forged high-alloy steel material and is made through multiple heat treatments and finishing. The sparse plate is made of highly wear-resistant stainless steel. It plays a role in guiding the material, cleaning the blades, and preventing the recovery of broken materials.

Leave a Comment