Treatment technology and prospect of waste circuit board recycling equipment

Circuit board recycling equipment occupies a place in the field of electronic waste treatment, and can be widely used for waste circuit boards, copper clad laminates, circuit board frame materials, etc. The waste circuit board (PCB) of the automatic waste circuit board recycling production line is a mixture of glass fiber reinforced resin and various metals. Its metal grade is equivalent to dozens to hundreds of metal grades in ordinary minerals, and its metal content is as high as 40%, is a typical electronic waste. Circuit board recycling equipment can recycle metal and other effective resources without causing any environmental pollution. It is an efficient and fully automatic recycling and processing waste circuit board production line that is more suitable for protecting the environment.

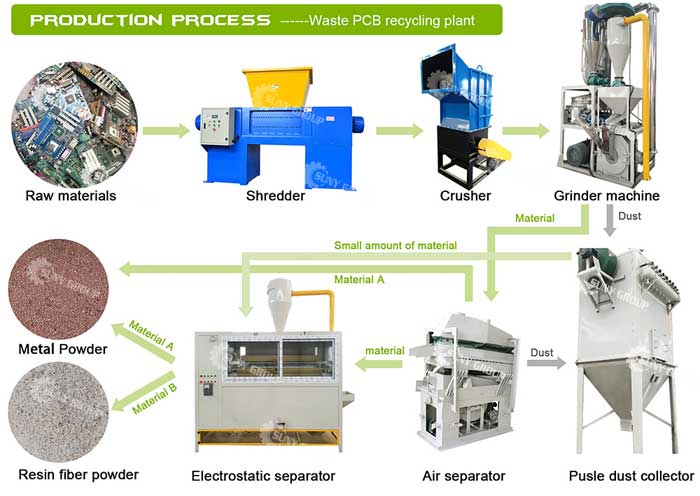

The whole line structure and process flow of circuit board recycling equipment: The circuit board processing and recycling production line is mainly composed of shredders, crushers, pulverizers, air flow specific gravity separators, high-voltage electrostatic separators and other auxiliary equipment.

1. Put the waste circuit boards into the first crusher, and use the roller crusher (first-stage crushing) to roughly crush the waste circuit boards, so that the circuit boards are broken into materials with a size of about 4CM, and then enter the belt type On the conveyor, the magnetic separator on the conveyor sorts out the iron in the material. The remaining material will be sent to the secondary pulverizer by the conveyor for crushing, making it a powdery mixture of metal and resin fiber powder; after crushing Under the action of the negative pressure fan, the material enters the No. 1 cyclone separator, and settles to the vibrating screen of the air flow separator through the external cyclone air flow of the cyclone separator. The light resin powder will be connected to the internal cyclone separator. The airflow enters the pulse dust collector. The materials entering the airflow separator are separated from metal powder and resin powder under the action of wind and vibration to obtain copper, resin powder and semi-finished products. The purity of the obtained copper can reach more than 85%, which can be sold directly.

2. The resin powder obtained will enter the No. 2 cyclone separator under the action of the fan, and the resin powder will settle into the screw conveyor along with the external swirling airflow, and then sent out, bagged and collected by the screw conveyor. The internal swirling airflow will bring light dust into the pulse dust collector. Under the filter of the dust bag, the dust settles to the bottom, and is sent out by the screw conveyor, bagged and collected. The filtered clean air is discharged from the top of the pulse dust collector. Among them, the semi-finished products obtained enter the electrostatic sorting machine through the closed screw conveyor, and are sorted again. The semi-finished products obtained by electrostatic sorting are basically materials that are not completely crushed and peeled off. The materials will enter through the screw conveyor. Go to the secondary pulverizer to pulverize again, and at the same time, electrostatic separation will get higher purity copper and resin products.

Waste circuit boards apply circuit board recycling equipment to the industrialized treatment of electronic waste. The circuit board recycling equipment crushing and separating device can crush and sort electronic waste such as waste circuit boards and copper clad laminates. For complex raw materials and metal content Different raw materials can be processed, the recovery rate is high, and the environment is protected.

Leave a Comment