Circuit board shredder separator

The circuit board shredder separator is suitable for recycling waste circuit boards, circuit boards, copper clad laminates and other electronic waste. The mixed metal and resin fibers are obtained through dry physical separation, and it can also be used to destroy the data on the circuit board. The mixed metals sorted out by the circuit board crusher separator can be sold directly, or used for gold extraction or purification, and can be sold at a good price. The separated resin fibers can be used to make building bricks, floor paints, wood-plastic products and other products.

1. Profit analysis of circuit board pulverizer separator Generally, the metals contained in circuit boards are: gold, copper, iron, lead, tin, nickel, antimony, and a small amount of rare and precious metals such as palladium and platinum. Copper metal can account for 90% of the mixed metals. % above, the current reference price of copper is around 64,000 per ton. The main profit of circuit board crushing and separation comes from the mixed metal, and the composition of the mixed metal depends on the composition of the circuit board. If the raw material is a computer board with relatively high precious metal content, the price of the sorted mixed metal will naturally be high, so the profit of the circuit board shredder separator can be imagined. learn more

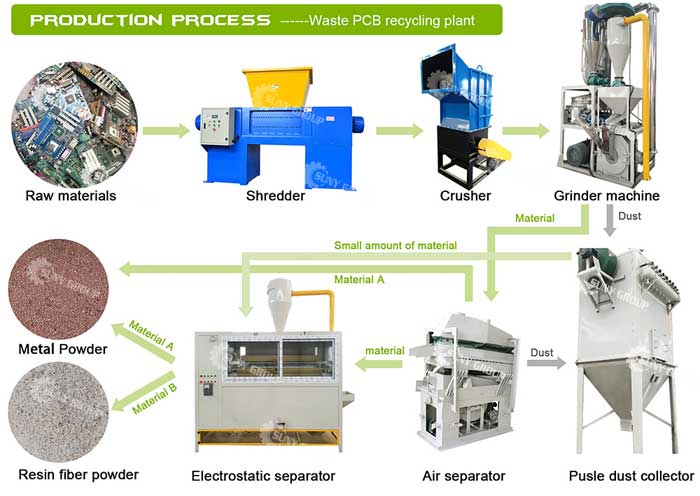

Second, the processing flow of the circuit board shredder separator The circuit board shredder separator can only obtain greater economic benefits if it reaches a high separation rate. The sorting process of Henan Dongying’s circuit board shredder separator is roughly as follows:

1. Waste circuit boards enter the shredder for pretreatment, and at the same time, the magnetic separator removes iron and selects iron with low value content.

2. The pretreated material goes through two crushers: hammer crusher and hammer crusher for fine crushing.

3. The crushed material enters the rotary vibrating screen, and the material whose diameter is too large will be sent back to the hammer crusher for secondary crushing, and the material whose diameter meets the standard will enter the sorting equipment.

4. The first sorting is carried out by the air flow specific gravity sorter, and the air flow specific gravity sorter will carry out preliminary sorting according to the different specific gravity of the material.

5. The second channel enters the electrostatic sorting machine, and fine sorting is carried out according to the different conductivity of the material, and the sorting rate can reach more than 99%.

The two crushing and two sorting processes fully guarantee the sorting rate of the circuit board shredder separator, and also ensure the economic benefits of circuit board crushing and recycling.

Leave a Comment