Recycling of precious metals from discarded computers and accessories

Electronic and electrical waste is usually pre-treated first, then manually dismantled and classified. After manual and mechanical assisted dismantling, various electronic components are separated, and the parts that can be used can be reused after reliability testing, and the toxic and harmful parts are treated separately. After dismantling, it can be recycled. At present, metals (including base metals such as copper, nickel, lead, tin, iron, and precious metals such as gold and silver) are mainly used for recycling waste computers at home and abroad. The technology for recycling precious metals is mainly divided into pyrometallurgy and hydrometallurgy. and mechanical methods. Pyrometallurgical technology mainly includes incineration and pyrolysis[12]. It refers to the use of high temperature to separate non-metallic substances and metal substances in components such as computer boards and cards. The scum floats on the upper layer of the molten metal material, which can be separated and removed. The precious metal forms an alloy with the base metal in the molten state. After removing the scum on the surface, pour the molten alloy into the corresponding mold to cool, and then make the precious metal and the base metal through refining or electrolytic treatment. Metal separation, while separating the precious metals from each other [13]. This method has high recovery efficiency and is simple, but it is prone to secondary pollution of waste gas and waste residue, and it consumes a lot of energy and expensive equipment.

Hydrometallurgy is also a widely used method for extracting precious metals from electronic waste, and it has been adopted by western developed countries as early as the 1970s. Waste particles are etched under acidic or alkaline conditions. The leaching solution After a series of processes such as extraction, precipitation, replacement, ion exchange, filtration and distillation, a high-grade and high-yield metal is finally obtained. In the process of hydrometallurgical treatment, strong acid and highly toxic cyanide are used, and the waste liquid produced contains heavy metals, cyanide and other substances, and the cost of wastewater treatment is high.

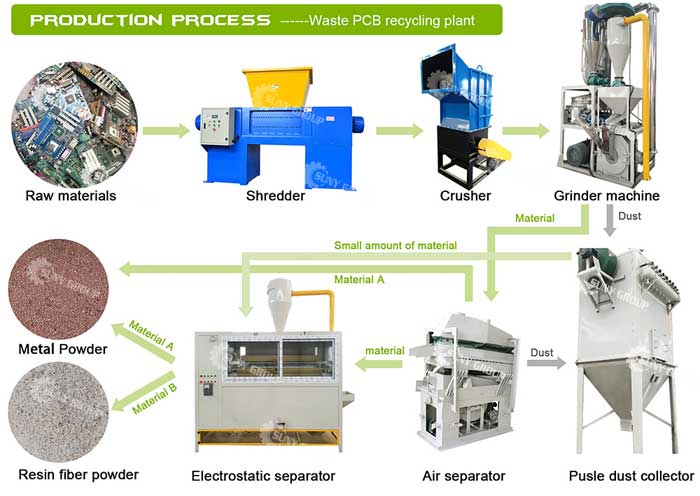

The mechanical method, also known as the physical method, is a method of recovering metals based on the differences in the physical properties of materials, such as density, conductivity, and magnetism [16]. Generally, the material is crushed to a suitable particle size by a crusher first, and then various materials are separated by magnetic separation, winnowing, electric separation, and flotation [17]. This method has the characteristics of low processing cost and less secondary pollution to the environment, and meets the current market demand, so it has certain advantages. Currently, this method is the fastest developing and most widely used method for recovering metals from e-waste.

Leave a Comment