A kind of waste circuit board recycling, crushing and separation equipment

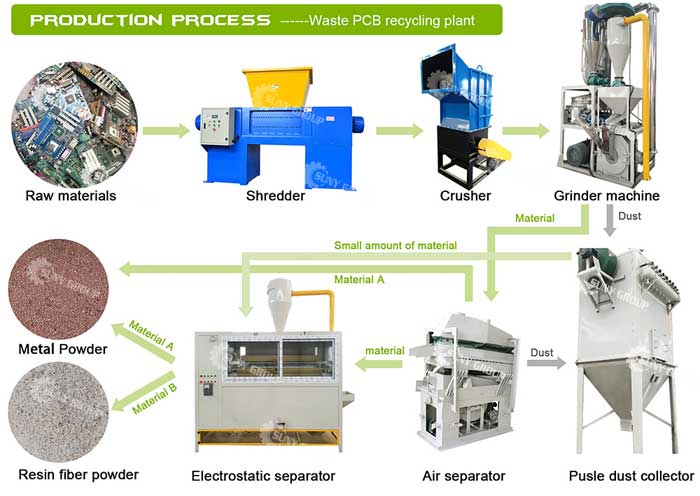

The main components of the circuit board are composed of epoxy resin fiber and copper. The printed PCB circuit board contains a large amount of metallic copper. Its resource recycling has always been a hot spot of attention for the recycling of waste electronic waste. The recycling of waste circuit boards is to recycle these circuit boards for recycling metal resources.

Crushing is the early stage of circuit board recycling. When it needs to be used, the large-volume circuit board is crushed into a small volume of 20-30mm. During the use of the current waste circuit board recycling crushing and separation equipment, a large amount of dust will be generated during crushing. It will spill out through the feeding port, resulting in serious air pollution in the workshop and affecting the breathing safety of workers.

The utility model relates to a recycling, crushing and separating equipment for waste circuit boards. By increasing the sealing performance of the equipment, the dust during crushing is prevented from spilling into the workshop, and the interior of the equipment where the dust is restricted ensures the air in the workshop is clean.

Compared with the prior art, the waste circuit board recycling, crushing and separation equipment: the crushing rollers are initially crushed, and the circuit boards after preliminary crushing are stacked on two sealing plates. After reaching a certain weight, the telescopic mechanism will be compressed to make the sealing The board is opened downward, and the upper circuit board will enter the bottom of the casing for secondary crushing. After the circuit board enters the bottom of the casing, the sealing plate will be closed to form a sealed cavity to avoid dust spillage during crushing and improve The air quality in the workshop is improved; the three sets of crushing blades with higher settings can quickly crush the circuit board, and the circuit board is more broken.

Leave a Comment