E-waste precious metal refining equipment

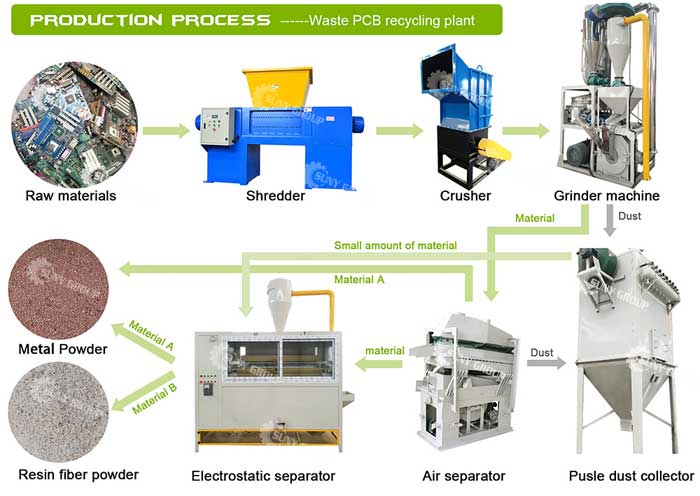

E-waste precious metal refining plants are specially designed to recover precious metals such as copper and aluminum from e-waste. The techniques used by these devices include chemical, physical and biological methods. The price and performance of these devices vary by manufacturer, but they are generally designed to recover precious metals.

It is true to extract gold from electronic products, but it is difficult to extract it with personal technology, and the purity in it is not high, so it is difficult to extract it. So for Xiaobai, there is really no need to do these things, and leave it to professionals, so don’t try to do such a project.

Precious metals such as gold and silver contained in waste electronic products can be extracted through smelting, so the recycling of waste electronic products, including the extraction of precious metals, is feasible. However, it should be noted that this process is an extremely complex and highly technical work, which requires professional equipment, technology and processes, and also needs to comply with the corresponding environmental protection regulations, otherwise it will cause serious harm to the environment and health .

In addition, as the designs of modern electronic products become smaller and smaller, the content of precious metals used is constantly decreasing, so extracting precious metals from some old electronic equipment may not be cost-effective, and it will also have a negative impact on the environment. Therefore, when recycling waste electronic products, in addition to refining precious metals, comprehensive recycling should also be carried out to minimize the impact on the environment.

In short, waste electronic products contain recyclable precious metals, but the refining process requires professional technology and equipment, and needs to comply with environmental protection regulations, otherwise it will cause harm to the environment and health.

Leave a Comment