How to properly dispose of circuit boards in discarded electronic waste?

With the acceleration of the updating speed of electronic products, the amount of discarded printed circuit boards (PCBs), which are the main components of electronic waste, is also increasing. The environmental pollution caused by waste PCBs has also attracted the attention of various countries. Waste PCBs contain heavy metals such as lead, mercury, and hexavalent chromium, as well as toxic chemicals such as polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE), which are used as flame retardant components. Groundwater and soil have caused huge pollution, which has brought great harm to people’s life and physical and mental health. On the waste PCB, there are nearly 20 kinds of non-ferrous metals and rare metals, which have high recovery value and economic value, and are a real mine waiting to be mined. What about next? I have sorted out several ways to deal with waste circuit boards and share them with you:

1 Physical method

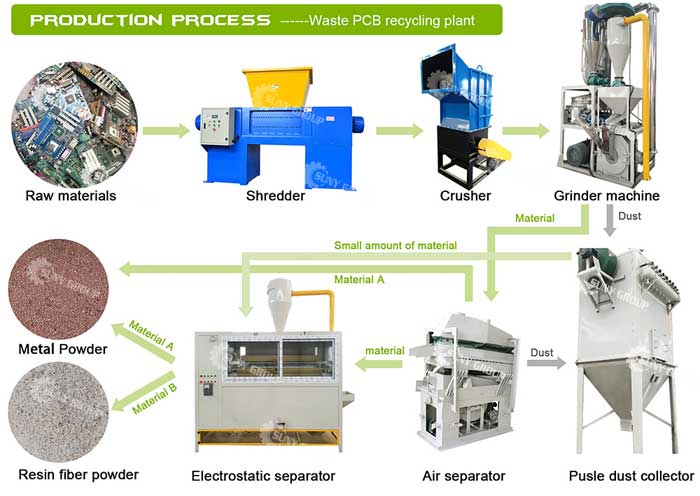

The physical method is a method of recycling using mechanical means and differences in the physical properties of PCBs.

The purpose of crushing is to dissociate the metal in the waste circuit board from the organic matter as much as possible, so as to improve the separation efficiency. The study found that when the fragmentation is 0.6mm, the metal can basically achieve 100% dissociation. Waste circuit board recycling is a highly applicable/environmental protection process. The physical method recycling process can effectively mechanically crush and recycle all kinds of waste printed circuit boards, processing waste, and waste electrical appliances. Its metal recovery rate is high and metal recycling The purity is as high as 96%.

The physical method is to use the difference between the mechanical equipment and the PCB process performance to complete the acquisition.

1.1 Smash

The purpose of crushing is to dissociate the metal in the waste circuit board from the soil organic matter as much as possible, so as to improve the screening efficiency. Research has found that when crushed at 0.6 mm, most of the metals can be dissociated 100%, but the crushing method and the selection of proportional series also depend on the subsequent processing technology.

1.2 Screening

Sieving is to use the difference in chemical properties of raw materials such as relative density, particle size distribution, electrical conductivity, conduction band magnetism and surface characteristics to complete the separation. At this stage, wind speed shaker technology, flotation agent separation technology, hurricane separation technology, sink-float separation and vortex screening technology are widely used at this stage.

Leave a Comment