Production process of medical protective masks

The production of mask machines is actually not complicated, starting from slitting non-woven fabrics, to origami machines, ultrasonic welding machines or resistance heat presses, edge banding machines, die-cutting or laser forming machines, laser coding machines, disinfection In fact, there are mature stand-alone equipment or head parts on the market, such as sterilization machines and the final baler. As long as the PLC action programming is done to coordinate the action beats, they can generally be assembled.

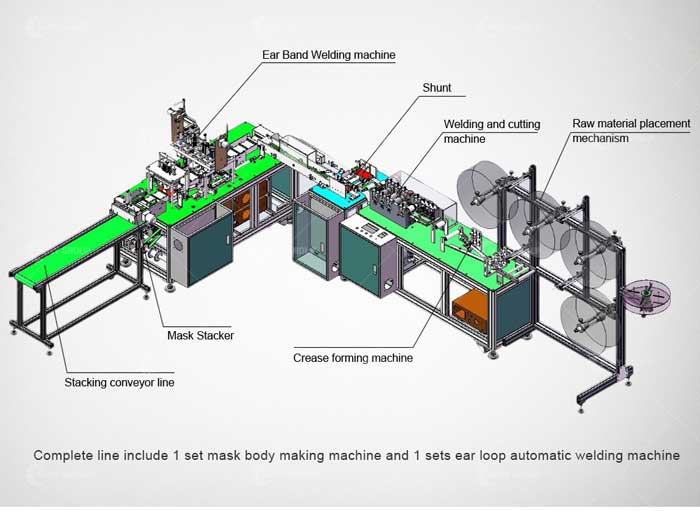

Fully Automatic Mask Making Machine 1+1

Mask forming → pressing → trimming → breathing valve welding → ear band spot welding → nose bridge line fitting → breathing valve punching → packaging → sterilization → analysis (EO sterilization) → finished product

The fully automated machine is relatively time-saving and efficient. The raw materials are hung on the material rack, the machine is automatically fed, and 2 to 3 ear belt machines are dragged by one body machine for automatic production.

The production of medical protective masks and masks is generally fully automatic or semi-automatic equipment.

Semi-automatic equipment includes mask forming machine, mask pressing machine, mask trimming machine, breathing valve punching machine (if there is a breathing valve), nose bridge line bonding machine, ear strap spot welding machine, breathing valve welding machine (if any Respiratory valve); Fully automatic equipment including automatic plane mask machine, automatic folding mask machine, etc., the cost is higher but time-saving and efficient.

Leave a Comment