Waste motor rotor recycling production line

Waste motor rotor recycling production line to handle size ≤ 15cm motor rotor (zone-axis)

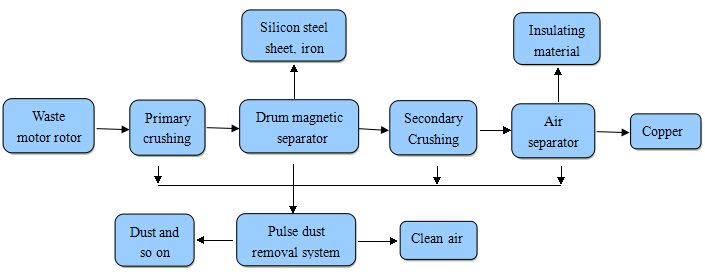

Waste motor rotor recycling production line Process description:

Using the drying type crusher, strong magnetic drum separator and air separator for crushing and sorting waste motor rotor, through professional equipment to disassemble waste motor rotor which is difficult to people. After processing, renewable resources will be got. The whole process conducted in the negative pressure.

Firstly, waste motor rotor is transported by conveyor to crusher for crushing, after that transport crushed mixed materials to strong magnetic drum separator separating non-ferrous metals (mixed materials) and silicon steel sheet (plate); Then the mixture of copper convey by conveyor to crusher for further crushing; And then through the air separator to get copper metal and nonmetal. Configuration in the process of crushing and sorting the pulse dust removal system, effectively solve the emission of dust, in line with the comprehensive pollutant discharge standards《GB16297-1996》.

Waste motor rotor recycling production line Craft diagram:

Waste motor rotor recycling production line Features:

1. Equipment with manual filtering operation system, as long as one click easily, the motor spindle will filter out, effectively solves the problem of difficulty to crush main shaft of waste motor rotor.

2. The production line is connected with each component; Crusher is durable, safe and reliable.

3. Configuration in the process of crushing and sorting the pulse dust removal system, effectively solve the emission of dust, in line with the comprehensive pollutant discharge standards《GB16297-1996》. Effectively avoid secondary pollution.

4. Equipped with hydraulic system, it is convenience to maintenance by staff.

5. The whole equipment control system adopts PLC control; it makes the coordination between system equipment, uniform feed.

6. Crusher lining is equipped with the protection board, effectively protect the machine.

Waste motor rotor recycling production line Parameters:

| Model | Capacity(kg/h) | Separation ratio | Dust removal ratio | Power(KW) |

| ZY-MC2000 | 2000 | >98% | >99% | 175 |

| ZY-MC3000 | 3000 | >98% | >99% | 210 |

| ZY-MC5000 | 5000 | >98% | >99% | 280 |

Leave a Comment